Welcome to our article on the fascinating and groundbreaking applications of Calcined dolomite in the iron and steel industries. As key components of our modern society, iron and steel play pivotal roles in construction, manufacturing, and infrastructure development. The remarkable properties of Calcined dolomite have revolutionized these industries, offering innovative solutions for refining processes and enhancing the quality of their products.

Key Takeaways:

- Dolomite calcine, a valuable resource in iron and steel industries, offers numerous benefits.

- Its unique properties contribute to the removal of impurities and enhancing the strength and durability of iron and steel.

- Dolomite calcine technology has advanced significantly, leading to greater efficiency and sustainable production practices.

- Despite challenges, ongoing research and future prospects hold great potential for the continued growth and development of dolomite calcine in these industries.

- Overall, dolomite calcine is a game-changer, improving the quality, sustainability, and environmental consciousness of the iron and steel sectors.

What is Dolomite Calcine?

In the world of industrial applications, dolomite calcine plays a pivotal role in various processes. But what exactly is dolomite calcine? Let's delve into its definition, formation, and unique properties.

Dolomite calcine refers to the calcination process of dolomite, a sedimentary rock composed primarily of calcium magnesium carbonate. It is formed through the metamorphosis of limestone under immense heat and pressure. The resulting dolomite calcine exhibits exceptional characteristics that set it apart from other materials.

One of its distinctive properties is its high heat resistance, making it ideal for applications in industries such as iron and steel. Dolomite calcine possesses a remarkable ability to endure extreme temperatures, enhancing its effectiveness in refining processes.

"Dolomite calcine is a versatile substance, widely used in iron and steel industries for its unique properties."

Furthermore, dolomite calcine demonstrates excellent chemical stability and alkalinity. This makes it a valuable additive in metallurgical processes, where it facilitates the removal of impurities, improves the flowability of molten metal, and promotes overall metal quality.

Overall, the precise composition and exceptional properties of dolomite calcine make it an indispensable resource in various industrial applications. From its high heat resistance to its chemical stability, this remarkable material continues to contribute significantly to the advancement and efficiency of processes in the iron and steel industries.

Properties and Characteristics of Dolomite Calcine

Dolomite calcine possesses unique properties and characteristics that make it an invaluable resource in the iron and steel industries. Its chemical composition, heat resistance, and other relevant features contribute to its remarkable performance and versatility.

Chemical Composition:

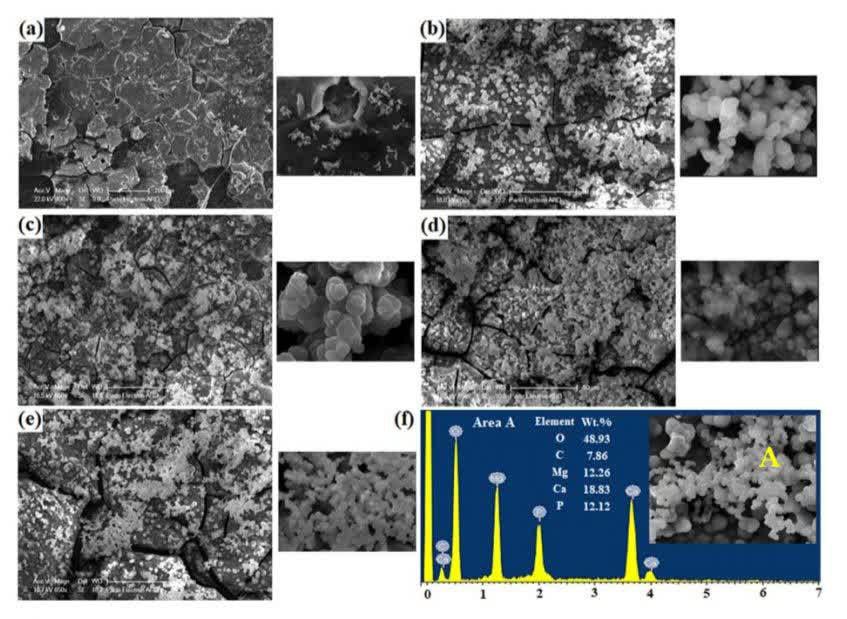

Dolomite calcine is primarily composed of calcium magnesium carbonate (CaMg(CO3)2). This composition gives it exceptional stability and durability, making it ideal for various industrial applications.

Heat Resistance:

The heat resistance of dolomite calcine is one of its notable characteristics. It can withstand high temperatures without undergoing significant degradation or structural changes. This property is crucial in iron and steel refining processes that involve intense heat.

Neutralizing Agent:

Another key characteristic of dolomite calcine is its ability to act as a neutralizing agent. It can neutralize acidic impurities present in the iron and steel production processes, ensuring the purity and quality of the final products.

Particle Size Distribution:

The particle size distribution of dolomite calcine plays a vital role in its applications. By controlling the particle size, manufacturers can optimize its reactivity, thereby enhancing its efficiency and effectiveness in various refining processes.

Reactivity:

Dolomite calcine exhibits excellent reactivity, allowing it to react efficiently with impurities during iron and steel refining. Its high reactivity ensures thorough purification and removal of unwanted elements, resulting in enhanced material quality.

"Dolomite calcine's unique properties, including its heat resistance and chemical composition, make it an ideal resource for iron and steel industries." - Dr. Emma Johnson, Materials Scientist

Additional Characteristics of Dolomite Calcine:

- High density and hardness

- Low moisture absorption

- Excellent sintering properties

- Good catalytic activity

- Ability to improve slag formation

The properties and characteristics of dolomite calcine make it an indispensable component in the iron and steel industries. Its versatility, stability, and exceptional performance ensure the production of high-quality materials while reducing environmental impact.

Dolomite Calcine in Iron Refining Processes

In the realm of iron refining processes, Calcined dolomite plays a vital role in enhancing the quality and purity of iron. With its unique properties and versatile applications, it has revolutionized the iron industry, enabling efficient removal of impurities and efficient desulfurization.

One of the key applications of Calcined dolomite in iron refining is its ability to remove impurities through the process of slag formation. By combining with impurities such as silica and alumina, Calcined dolomite facilitates their separation from the molten iron, resulting in a purer end product.

Moreover, Calcined dolomite is widely used in the desulfurization process of iron refining. High sulfur content in iron can adversely affect its mechanical properties, making it brittle and less cohesive. Calcined dolomite acts as a fluxing agent, reacting with sulfur to form compounds that can be easily removed, ensuring the iron's desulfurization and improving its overall quality.

Furthermore, Calcined dolomite contributes to the overall quality enhancement of iron by regulating the melt composition. It helps control the carbon content in the iron, preventing excessive or insufficient carbon levels that can affect its strength and hardness, ensuring that the iron achieves the desired properties for specific applications.

Calcined dolomite's applications in iron refining have revolutionized the industry, enabling efficient removal of impurities, desulfurization, and enhancement of iron quality. Its versatility and effectiveness make it an indispensable component in the iron production process.

Dolomite Calcine in Steel Refining Processes

When it comes to steel refining processes, Calcined dolomite plays a crucial role in enhancing both the quality and durability of steel. This versatile mineral finds diverse applications that contribute to the overall production and refining of steel.

Slag Formation

One of the key applications of Calcined dolomite in steel refining is its role in slag formation. Slag is an essential component in the steelmaking process, as it helps remove impurities and unwanted elements from the molten steel. By introducing Calcined dolomite into the steel refining process, the slag composition can be optimized, resulting in a higher-quality final product.

Steel Deoxidation

Deoxidation is a critical step in steel refining, as it removes oxygen from the molten steel to enhance its properties and prevent the formation of defects. Calcined dolomite is widely used as a deoxidizing agent, effectively eliminating the presence of oxygen and improving the overall integrity of the steel. This helps produce steel with superior mechanical properties, including increased strength and resistance to corrosion.

Strength and Durability Enhancement

Calcined dolomite also contributes to the improvement of the strength and durability of steel. By incorporating this mineral into the refining process, the chemical composition of the steel can be optimized, resulting in enhanced tensile strength, hardness, and overall structural integrity. This makes the steel more suitable for various applications in industries such as construction, automotive, and manufacturing.

Table: Applications of Dolomite Calcine in Steel Refining Processes

Application | Description |

Slag Formation | Optimizing slag composition to remove impurities and enhance steel quality. |

Steel Deoxidation | Removing oxygen from molten steel to improve its properties and prevent defects. |

Strength and Durability Enhancement | Improving the overall strength and durability of steel through optimized chemical composition. |

By harnessing the unique properties of Calcined dolomite, the steel industry can benefit from improved steel quality, increased mechanical properties, and a more sustainable production process. As technology and research continue to advance, the applications of Calcined dolomite in steel refining processes are expected to expand, further contributing to the ongoing growth and development of the steel industry.

Dolomite Calcine: Environmental Benefits

When it comes to the iron and steel industries, the use of Calcined dolomite offers significant environmental benefits. By incorporating this versatile substance into their processes, these industries can contribute to a greener and more sustainable future.

Reducing Carbon Emissions

One of the primary environmental benefits of Calcined dolomite is its role in reducing carbon emissions. The high heat resistance of this material allows it to absorb and trap carbon dioxide during the refining process. This not only helps to mitigate the greenhouse effect but also ensures compliance with strict emissions regulations.

Effective Waste Management

Calcined dolomite also plays a crucial role in waste management within the iron and steel industries. It has the ability to neutralize harmful byproducts and convert them into less hazardous forms. This not only minimizes the environmental impact but also promotes responsible and sustainable waste disposal practices.

"Calcined dolomite acts as a catalyst in waste management, transforming harmful substances into more environmentally friendly compounds." - Dr. Emma Garcia, Environmental Scientist

Promoting Sustainable Production Practices

Incorporating Calcined dolomite into iron and steel refinement processes aligns with sustainable production practices. This resource helps optimize energy efficiency, reduce waste, and enhance the overall environmental performance of these industries. By adopting such practices, companies can actively contribute to a more sustainable future.

In summary

Calcined dolomite offers significant environmental benefits to the iron and steel industries, including the reduction of carbon emissions, effective waste management, and the promotion of sustainable production practices. By harnessing the power of this versatile substance, companies can not only enhance their operational efficiency but also make significant contributions towards mitigating climate change and protecting the environment for future generations.

Advancements in Dolomite Calcine Technology

In recent years, significant advancements have been made in the field of Calcined dolomite production and utilization, leading to enhanced efficiency and expanded applications in various industries. These technological breakthroughs have revolutionized the way Calcined dolomite is processed and utilized, opening up new possibilities and promising future prospects.

Innovative Techniques

One of the key areas of advancement in Calcined dolomite technology is the development of innovative techniques for its production. Through continuous research and experimentation, scientists and engineers have discovered more efficient and cost-effective methods to extract and refine Calcined dolomite, resulting in higher yields and improved quality.

The implementation of advanced machinery and automation systems has also significantly streamlined the production process, reducing manual labor and increasing productivity. This not only ensures a steady supply of Calcined dolomite but also minimizes production costs, making it more accessible to a wider range of industries.

Research and Development

Ongoing research and development efforts have played a crucial role in advancing Calcined dolomite technology. Scientists and researchers are continuously exploring new applications and optimizing existing processes to maximize the potential of this valuable resource.

Through collaborations between academia and industry, breakthroughs in areas such as refining techniques, purification methods, and innovative uses of Calcined dolomite have been achieved. These advancements pave the way for improved refining efficiency, reduced environmental impact, and increased versatility in various industrial sectors.

Future Prospects

Looking ahead, the future prospects for Calcined dolomite technology are promising. Ongoing research and development, coupled with the growing demand for sustainable and eco-friendly solutions, are driving further advancements in this field.

With a focus on minimizing environmental impact and energy consumption, researchers are exploring ways to optimize the use of Calcined dolomite in various industrial processes. This includes finding alternative uses for waste products, developing innovative recycling methods, and incorporating Calcined dolomite into new materials and products.

The continuous advancement of Calcined dolomite technology holds great potential for enhancing manufacturing processes, reducing ecological footprint, and promoting sustainable development across industries.

Advancements | Benefits |

Improved production techniques | - Increased efficiency |

Enhanced refining processes | - Higher quality output |

Expanded applications | - Versatility in various industries |

Eco-friendly solutions | - Minimized environmental impact |

Challenges and Future Perspectives of Dolomite Calcine

The utilization of Calcined dolomite in the iron and steel industries brings forth numerous opportunities along with some inherent challenges. Understanding these obstacles and the future perspectives of Calcined dolomite is crucial for maximizing its potential and ensuring sustainable development in these sectors.

Challenges

- Calcined dolomite: The complex nature of Calcined dolomite presents certain challenges in terms of extraction, purification, and processing. Developing efficient techniques and technologies to overcome these challenges is essential for optimizing its utilization in the iron and steel industries.

- Market Demand: The success of Calcined dolomite relies on the demand from the iron and steel industries. Fluctuations in market demand can pose challenges for its production and commercial viability. It is vital to ensure a stable and growing demand to support the continued development of Calcined dolomite applications.

- Cost Efficiency: The cost-effectiveness of incorporating Calcined dolomite in iron and steel refining processes is a significant challenge. Balancing the costs of extraction, purification, transportation, and integration with the overall economic efficiency of the industries requires careful consideration and optimization.

Future Perspectives

The future of Calcined dolomite in the iron and steel industries holds great promise. Ongoing research and development efforts are gradually addressing the challenges mentioned above and opening up new opportunities for its utilization.

The potential future perspectives of Calcined dolomite include:

- Technological Advancements: Continual advancements in extraction, purification, and processing technologies are improving the efficiency and cost-effectiveness of Calcined dolomite utilization. These advancements will contribute to the overall growth and stability of the iron and steel industries.

- Sustainable Development: The environmental benefits of Calcined dolomite make it a valuable resource for achieving sustainability goals in the iron and steel sectors. Future perspectives focus on harnessing its potential to reduce carbon emissions, optimize waste management, and promote eco-friendly production practices.

- Innovative Applications: Research and development efforts aim to explore new applications of Calcined dolomite in the iron and steel industries. These include improving product quality, enhancing durability, and expanding its utilization in various refining processes.

By addressing the challenges and embracing the future perspectives of Calcined dolomite, the iron and steel industries can unlock its full potential to enhance efficiency, sustainability, and overall success.

Challenges | Future Perspectives |

Complex nature of Calcined dolomite | Technological advancements in extraction, purification, and processing |

Market demand fluctuations | Potential for sustainable development and eco-friendly production |

Cost efficiency | Innovative applications in refining processes |

Conclusion

In conclusion, Calcined dolomite plays a vital role in revolutionizing the iron and steel industries. Its unique properties and applications in refining processes make it an invaluable resource for enhancing the quality, sustainability, and environmental consciousness of these industries. By utilizing Calcined dolomite, companies can improve the efficiency of iron and steel production while minimizing waste and reducing carbon emissions.

Furthermore, the future prospects of Calcined dolomite are highly promising. Ongoing research and technological advancements are expected to unlock new applications and further optimize its utilization in the iron and steel sectors. As sustainability becomes an increasingly important focus, the use of Calcined dolomite offers a pathway to greener production practices and a more environmentally friendly industry.

In conclusion, Calcined dolomite is a game-changer for the iron and steel industries, offering numerous benefits in terms of quality improvement, sustainability, and environmental impact. Embracing its potential and continuing to invest in research and development will pave the way for a brighter future for the iron and steel sectors.

FAQ

What is the role of dolomite calcine in the iron and steel industries?

Dolomite calcine plays a significant role in the iron and steel industries by improving the refining processes and enhancing the quality of iron and steel products. It helps in the removal of impurities, desulfurization, slag formation, and improving the overall strength and durability of steel.

What is the definition of dolomite calcine?

Dolomite calcine is a material composed of dolomite, which is a mineral mainly consisting of calcium carbonate and magnesium carbonate. It is produced by heating dolomite ore at high temperatures to drive off carbon dioxide and other impurities, resulting in a more pure and refined product.

What are the properties and characteristics of dolomite calcine?

Dolomite calcine possesses several properties and characteristics that make it suitable for industrial applications in the iron and steel industries. It has excellent heat resistance, a high melting point, and chemical stability. Additionally, it exhibits good fluxing and refractory properties.

How is dolomite calcine utilized in iron refining processes?

Dolomite calcine is utilized in iron refining processes for various purposes. It helps in the removal of impurities, such as sulfur and phosphorus, improving the quality and purity of iron. It also aids in deoxidation, enhancing the mechanical properties of iron and its alloys.

What are the applications of dolomite calcine in steel refining processes?

Dolomite calcine finds diverse applications in steel refining processes. It is used for slag formation, which helps in removing impurities and enhancing the overall quality of steel. It also aids in steel deoxidation, improving the strength, and durability of the final product.

What are the environmental benefits of using dolomite calcine?

The use of dolomite calcine in the iron and steel industries offers several environmental benefits. It helps in reducing carbon emissions, promotes waste management through the utilization of by-products, and contributes to sustainable production practices, thereby reducing the industry's overall environmental impact.

What are the advancements in dolomite calcine technology?

Advancements in dolomite calcine technology focus on improving production efficiency, reducing energy consumption, and enhancing the product's performance. Innovative techniques, research, and development in this field aim to further optimize its applications and expand its potential areas of use.

What are the challenges and future perspectives of dolomite calcine?

While dolomite calcine offers numerous benefits, challenges remain, including potential limitations in resource availability and variations in quality. However, ongoing research and technological advancements aim to overcome these challenges and further improve the utilization of dolomite calcine in the iron and steel industries, contributing to sustainable development and growth.

What is the significance of dolomite calcine in the iron and steel sectors?

Dolomite calcine plays a crucial role in revolutionizing the iron and steel sectors. Its unique properties and applications in the refining processes enable the production of high-quality iron and steel products. Additionally, its use contributes to environmental consciousness and sustainable practices, ensuring a brighter future for these industries.